packaging creep test|metal creep test pdf : manufacturer The creep test can then be conducted by inflating the sealed package to 80 percent of the burst test benchmark and measuring the length of time or ‘creep’ until package failure. The creep test checks to see whether . webAlbum: SolaZola [1133 files :: 557.11 MB] on CyberDrop.me [Reg: OPEN] - A privacy-focused censorship-resistant file sharing platform free for everyone. Upload files up to 200MB. Keep your uploads safe and secure with us 🔐

{plog:ftitle_list}

Resultado da Join Club 250. Chat in Discord. Follow on Steam. Top 150 best Steam games of all time tagged with Hentai, according to gamer reviews. This is the free version of this page. An enhanced version of this tag is available on Club 250. The enhanced version includes an extensive tag description and a list of .

Creep Testing. Creep is the deformation of a material occurring with time due to an externally applied constant stress. For cushioning materials specifically, it may be defined as the change in thickness of a cushion under static compressive load over a period of time. The creep test can then be conducted by inflating the sealed package to 80 percent of the burst test benchmark and measuring the length of time or ‘creep’ until package failure. The creep test checks to see whether the . The creep test can then be conducted by inflating the sealed package to 80 percent of the burst test benchmark and measuring the length of time or ‘creep’ until package failure. The creep test checks to see whether .Creep testing on plastics and composites Material Meets Engineering 2019 June 18, 2019 Lukas Unger. The Stepped Isothermal Method (SIM) offers savings of time and costs by temperature steps on 1 specimen. 6. Applications.

We have wholesale testing equipment for different equipment testing needs. Quality packaging creep testing equipment will help with efficient testing of electronic equipment. All categories. Featured selections. Trade Assurance. Buyer Central. Help Center. Get the app. Become a .Perform burst, leak, creep, creep to fail and bubble tests from one instrument – or try the combined test option to conduct a simultaneous leak, creep and burst test on a single package. It is ideal for testing rigid, semi rigid and flexible packaging, as well as porous and laminated foils for the food, pharma and medical industries.

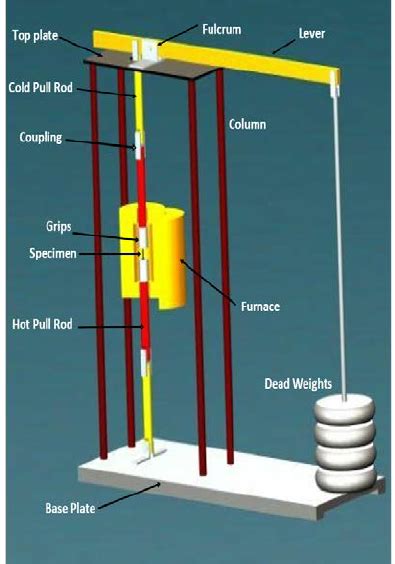

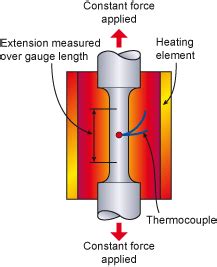

Creep And Creep Testing To do creep testing, a tensile specimen is subjected to steady tension at a constant temperature, usually by suspending weights from it. The results of the test are plotted as a function of strain over time. When metals are subjected to high temperatures, a failure mechanism known as creep can become [.]Creep testing is used for flexible packaging of differing sizes and seal configurations. ASTM F2096: Bubble emission test; The bubble emission test uses water, rather than internal pressure, to identify packing seal issues. Packaging is submerged underwater, and the technician will watch for any steady stream of bubbles. If that occurs, it is a .

Creep Test: Creep testing evaluates the deformation or stretching of packaging materials over time. It is vital for assessing long-term structural integrity and stability. Particularly relevant in industries where packaging materials are subjected to prolonged stress or pressure, such as in storage or transportation.Creep Test The creep test, also known as the stress relaxation test, is a destructive way of evaluating a material’s durability and thermal stability. . Packaging Material . ASTM F88; ASTM F3039; ASTM F1608; ASTM D7709; ASTM D7734; ASTM D3330; ASTM E1417; ASTM D6834-02; Iron and Steel Products . ASTM E572-13; ASTM E572; ASTM E1086; ASTM .We’ve been designing and building instruments to test films and flexible packaging for several decades. If you work with films, our inspection devices will ensure the quality and . integrity of your films and flexible packaging. • Burst, creep, and leak testing • Density testing • Environmental stress crack testing • Friction and .

ASTM F1140 (Burst test) measures the pressure at which the package will burst. This standard test method determines the ability of packages to withstand internal pressurization. Burst test is a whole-package test-to-failure, it is not location-specific. Within ASTM F1140, there are three methods: Burst Test, Creep Test, and Creep to Failure.An example of a pouch leak failure includes a seal failure or packaging material failure. Creep Testing. Creep testing maintains a set pressure for a specific time. The testing can also result in a failure. The test measure is pass or fail. The starting pressure is a percentage of the burst pressure. The typical starting point is 80%.The primary objective of package integrity testing is to detect packaging issues and to prevent any form of damage to the product before being dispatched to customers. The packaging also has an immense impact on the perception of quality by the consumers. . Several testing methods are available and have been extensively used to determine seal .

We perform test according to ASTM standards for medical trays and pouches. Package integrity, seal integrity and seal strength. Let our experts advise you to choose the right test for your medical packaging. Bubble Leak Test Burst & Creep Test Seal Strength (Peel Test) Visual Integrity Inspection Dye Penetration Test Bubble Leak Test Bubble Leak Test This test .It could be a seal failure or packaging material failure. ASTM F1140 may be tested with or without the packaged product. Furthermore, it may be tested either open or closed. Creep Testing. Creep testing maintains a set pressure for a specific time. The testing can also result in failure. The test measure is pass or fail.

Packaging Test Summary. Basic Packaging Validation Plan. Real Time Aging – post aging testing. Accelerated Aging – post aging testing . Burst / Creep Test. Burst Test - ASTM F1140. Determines package seal strength. Test system pressure is pre-set to a point above the known burst point. Perform by pressurizing the

Category 1: Packaging Testing. Gurley Method Air Permeance Determination April 27, 2017. Visual Inspection of Medical Packaging to Determine Integrity April 27, 2017. . Burst and Creep Package Evaluation Tests April 27, 2017. Instron Testing of Materials April 27, 2017. Package Seal Dye Penetration April 27, 2017. Careers;ASTM F1140 evaluates the response of flexible packaging subjected to internal pressure. The method is applicable to a variety of packaging sizes, shapes and seal configurations and may be performed at stages along the packaging life .An article on creep and creep testing. Creep is a slow failure mechanism which may occur in a material exposed for a protracted length of time to a load below its elastic limit. Testing is conducted using a tensile specimen to which a constant stress is applied

what is creep testing

Unlike metals, polymers can creep at room temperature under constant loads. The viscoelastic nature of polymers means their creep response is influenced by both elastic and viscous properties. Polyethylene and polypropylene, used in piping and packaging, can deform under sustained stress, necessitating careful design to prevent long-term .

ทั้งหมดเรื่องรั่วซึมในบรรจุภัณฑ์อาหาร burst, creep, and creep-to-failure test in food packaging Food Package Testing TME is aware of the many variations on the need to test food packaging, such as the degree of permeability of the package and the strength of the seal to .Package integrity testing after production is a key factor in knowing whether your processes are under control. We offer package testing instruments that measure whole package permeability, package burst/creep limits, package leaks and gas composition in modified atmosphere packaging (MAP). We have the tools and experts to help you with your package integrity .Creep strain testing can be carried out in a controlled environment up to temperatures of 80°C. The resulting data is used to calculate the creep modulus. Creep Rupture Creep rupture is a measure of failure time as a function of applied stress. A range of applied stresses are used to generate failure times, typically from 100s to 106s.

Burst test: Technology : Barometric Accuracy : +/- 0,5% full scale Resolution : 1mbar Flow scales : 0,2 – 1,4 bar Quick inflating flow : Minimum 250l/h Burst pressure : Up to 1,4 bar Analytical curves (displayed and recordable) or Creep test Technology : Barometric Accuracy : +/- 0,5% full scale Resolution : 1mbar Measurement : 200 – 500 mbar

Pharmaceutical & Medical Packaging News staff . ISO 11607 addresses two types of seal-strength testing: tensile strength testing and burst or creep testing. Pull it apart. Tensile seal-strength testing (ASTM F88) uses a defined width sample (25.4 mm or 1 in.) of the package seal perimeter. A jaw moving at a defined constant rate (10–12 in .ASTM D7030 Creep Testing of Corrugated Fiberboard Containers. The ASTM D7030 test method covers the resistance of corrugated containers to a constant compression load. As an ISTA and ISO 17025 certified lab, we realize the importance of creep testing. Meeting the ASTM D7030 requirements can be difficult.Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups . 1.3 The creep test maintains a specified pressure for a specified time or until the package fails (Creep Test & Creep to Failure Test). Inflation seal-strength testing (ASTM F1140 and ASTM F2054) includes burst, creep, and creep-to-failure testing. Burst testing pressurizes the entire package and captures the peak rupture pressure. This test provides a whole-package minimum seal strength, and is equally applicable to peelable and nonpeelable seals.

metal creep test pdf

WEBTS Elloah | Elloah Guedes pictures and videos on EroMe. The album about TS Elloah | Elloah Guedes is to be seen for free on EroMe shared by MadeYouCurious. Come see and share your amateur porn.

packaging creep test|metal creep test pdf